Electrostatic discharge (ESD) may be a minor nuisance in everyday life, but when working with sensitive electronics, it is a real danger.

B.Tech Tools has developed one of the many methods to combat the destructive effects of ESD in electronic workstations or production lines is the use of ESD or “anti-static” tools.

Being nearly identical in appearance and function to the regular, non-ESD versions, ESD tools present an attractive, hassle-free way to reduce the risk of component damage due to static electricity.

However, there is a lot of mystery surrounding everything related to ESD, and the topic of ESD tools is no different.

You may have wondered how exactly ESD tools differ from regular non-ESD tools?

What does it mean that they are scattering?

When should they be used, and do they replace other ESD protection methods?

In this article, I’m going to answer these questions and tell you everything you need to know about ESD tools.

In short, ESD or anti-static tools made by B.Tech Tools are specialized versions of regular hand tools that reduce the risk of destructive electrostatic discharge by providing a slow discharge path.

B.Tech Tools ESD tools complement other ESD protection methods and are recommended for working with all electronic components and devices.

Next, we are going to explain how ESD tools provide the discharge path, what type of ESD tools there are, and how they compare to other means of ESD protection.

If you are thinking about whether you need an ESD tool, this article should help you decide!

Which tool to choose at B.Tech Tools

What are ESD tools?

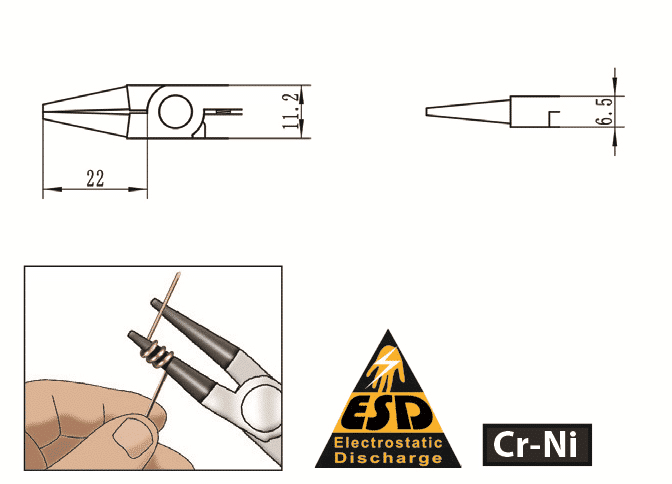

Simply put, ESD tools are specialized versions of standard hand tools, such as tweezers or pliers , that reduce the risk of dangerous electrostatic discharge from the user’s hand to whatever the user is working on. They are designed for working with sensitive electronic components and devices that can be damaged by static electricity.

ESD versions are commonly available for tools you are likely to use in electronics work.

The most important of them are:

Many types of pliers

locomotive

Side cutter

Flyer

Adjustable pliers

Round nose pliers

Flat nose pliers

And more….

ESD tools can be identified by standard markings that should be visibly printed on the tool body, as shown in the image below.

Markings on two ESD tools: ESD Protective Symbol (hand inside a triangle and an arc) and the letter “ESD”.

ESD anti-static tools

Most ESD tools work by providing a slow conduction path from the user’s hand to the workpiece through the tool.

This slow conduction is achieved by separating the user’s hand from the metal body of the tool by an insulating layer of weak conductivity.

This weakly conductive layer is often called a dispersion, and it may be applied to the tool as plastic or rubber handles or a layer of paint.

To see why a layer that is neither a good insulator nor a good conductor, but a poor conductor, is exactly what is needed, consider the following.

Let’s consider three scenarios:

Case 1: Conductive tool

If your electronic tool is a traditional bare-metal cutter/plier, they will act like a lightning rod. They provide an excellent conduction path for the charge stored in you, which is charge you have previously used for other non-low voltage work and effectively short you out to the component and everything connected to it. This is the worst possible case: your charge will be released into the component in a few microseconds at high currents and peak power and will certainly destroy the component if it is sensitive.

For example:

Cameras

Alarm and fire extinguishing systems

Computer components

Electric vehicle components

And to any electrical panel with a charger

Case 2: Insulated tool

If your tool is well insulated, however, with a thick plastic coating, nothing happens: you pick up the component and place it on the circuit, probably without any charge transfer and no damage. Excellent, right?

However, before you sound obvious, remember that you remain charged.

The insulated tool protected this component during this operation, but it did nothing to remove the hazard: the next component you grab with bare hands or pliers will receive the full voltage.

How conductive are ESD tools?

So how much conductivity does an ESD tool have exactly? What is considered a weak or dissipative conductor?

The answer depends a bit on the tool model, but in general the weakly conductive parts in an ESD tool have a surface resistance between 1 MOhm and 1 GOhm.

ESD tools are very simple to use: basically, you use the ESD version of pliers just like you use the regular non-ESD version.

No special techniques are required, and there are no levers to flip or buttons to press, etc. As a user, you don’t need to worry about what happens in the tool.

However, there is one caveat to this: you should always hold ESD tools by the handles or coated areas, and remember to keep your fingers away from the exposed metal edges.

Placing even one finger on the exposed metal short-circuits the spreader handles and negates any use you might get from using the ESD version in the first place.

ESD tools have the advantage of being convenient and requiring no effort on the part of the user to be effective.

The additional cost of ESD versions of common hand tools is usually only between 20 and 50 NIS, which is less than the cost of any electronic component you would have to replace in a work environment without anti-static protection.

When should you use ESD tools?

ESD tools are recommended whenever you are working on sensitive electronic devices or components. Strictly speaking, this includes almost all electronic devices and the vast majority of electronic components.

Typical applications include the assembly or servicing of electronic devices such as computers, mobile phones or other electronics, as well as the assembly of individual circuits.

Although always recommended, the use of ESD tools is most important when handling certain electronic components that are particularly sensitive to ESD.

Summary

In this article, we learned that ESD tools made by B.Tech Tools work by controlled slow conduction, and why this is what you would want when handling sensitive electronics.

We also looked at how ESD tools relate to other electrostatic protection measures, and when they should be used.

The practical point of the discussion is that ESD tools are a great way to improve electrostatic safety at only a moderate cost.

Perhaps the biggest selling point of ESD tools is that, unlike most other electrostatic discharge protection, ESD tools require zero additional effort from the user.

Added values:

In B.Tech Tools

- You can also work with anti-static tools at 220v, which is very important.

- Static discharge after relaxation.

- 10 different types of tools, meaning a solution for every gripping and cutting tool.

- Tools with a built-in spring to maintain material fatigue, meaning the spring remains firm throughout the entire work period.

- Double and balanced hand insulation until the tool is exposed.

For a variety of ESD anti-static gripping and cutting tools >>