Description

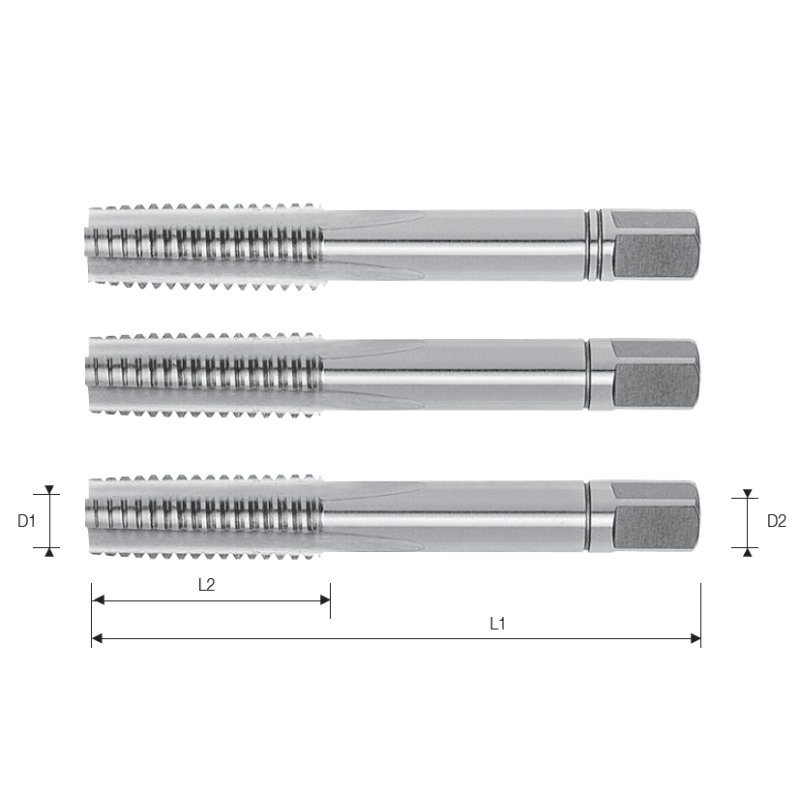

CO DIN352 Tap Set – Professional Performance for Precise Tapping

The CO DIN352 tap set from B.Tech offers a professional solution for precise, fast, and long-lasting tapping.

The taps are made of M35 HSS COBALT , an extremely strong material that allows for sharp cutting, reduced wear, and resistance to high temperatures .

Thanks to an advanced vacuum reinforcement process , which lasts 48 hours, the structure becomes especially durable and allows for maintaining excellent performance even during prolonged use .

To ensure uniform taping, each unit undergoes pressure testing and precision grinding , so that the result is smooth and without deviations.

If you are looking for a reliable tool that does the job with maximum precision – this is the set for you.

Product benefits

- Maximum precision in threading – sharp cutting that ensures uniform threading

- Vacuum-strengthened for 48 hours – improves durability and prevents premature wear

- Suitable for sanding a variety of materials – ideal for steel, iron and alloys

- A perfect solution for professional work – suitable for industrial use and maintenance

- Rigorous manufacturing process – including precise grinding and comprehensive pressure testing

Technical specifications

- Model: CO DIN352

- Material: M35 HSS COBALT

- Production technology: vacuum hardening for 48 hours

- Processing process: Production and grinding under controlled conditions

- Uses: Suitable for grinding steel, hard metals and alloys

Common uses

- Creating precise threads in the metal and chip processing industries

- Fast and efficient tapping even in challenging work environments

- Precision cutting in the automotive and machinery industry

- Maintenance and overhaul of industrial components

- Work in frames, renovations and manufacturing of mechanical components

Why choose B.Tech’s CO DIN352 tap set?

- Vacuum-strengthened for 48 hours – ensures high durability

- Sharp and clean cutting – ensures smooth threading without deviations

- Fully suitable for professional work – designed for industry and advanced maintenance

- Maximum precision – allows uniform tapping in all working conditions